Roll Stands & Tension Stands

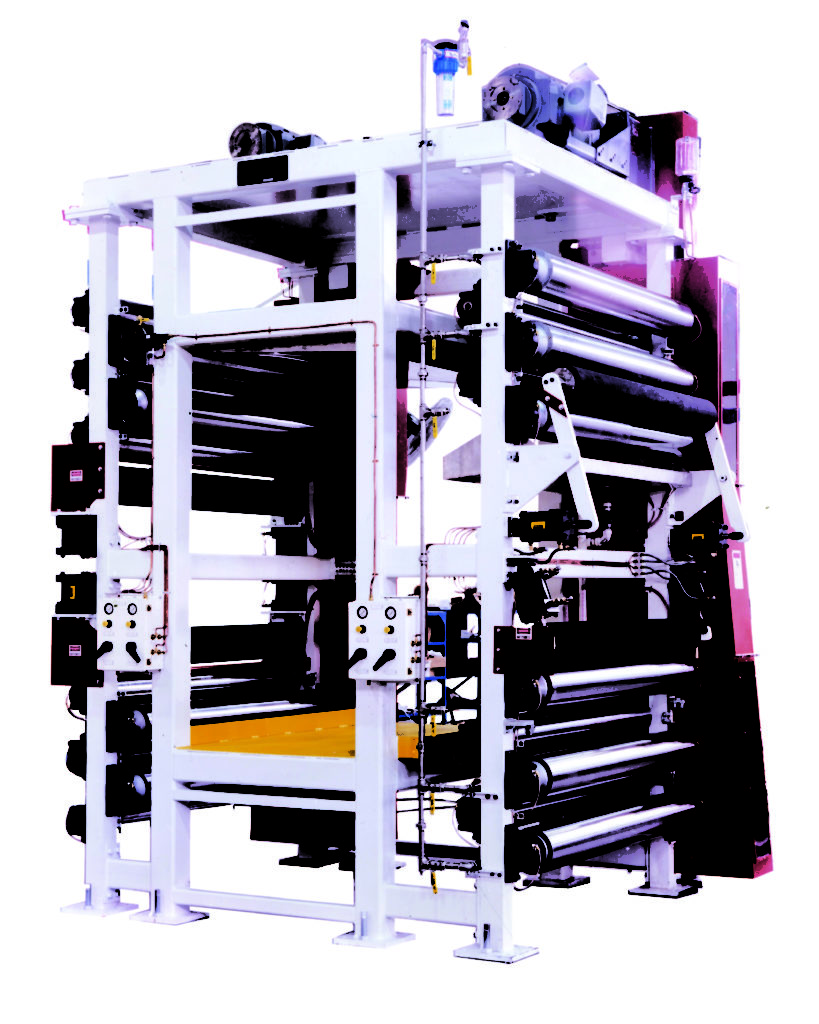

Roll Stands

Roll Stands are required to evenly transport the fiber tow through the Oxidation Ovens. Litzler has a long history of machine building in addition to building ovens.

- Roll stands are engineered to minimize deflection to ensure even tow tracking

- Smooth or grooved roll designs depending on tow size and customer preference

- Design includes roll alignment fixtures for setting tow tracking while the tow is under production tension loads

- Driven and idler rolls

- Direct driven and multiple driven designs

- Bowed rolls for tow spreading

- L10 bearing life design (minimum 40,000 hours)

- Centralized lubrication for easy maintenance

- Integrated platforms and seismic bracing based on seismic region

- Rolls are designed using Litzler’s standard deflection criteria to minimize deflection under load and keep the tow bands evenly spread

- Stand structures are designed using CFD analysis to maintain integrity under load to maintain tow tracking

- Roll diameters are designed based on oven width and total tension

- Roll finishes down to 1Ra

- Chrome plated (matte or mirror finish)

- Tungsten carbide coatings available for traction and abrasion resistance

- Load cell tension monitoring is available and integrated through Litzler Automation

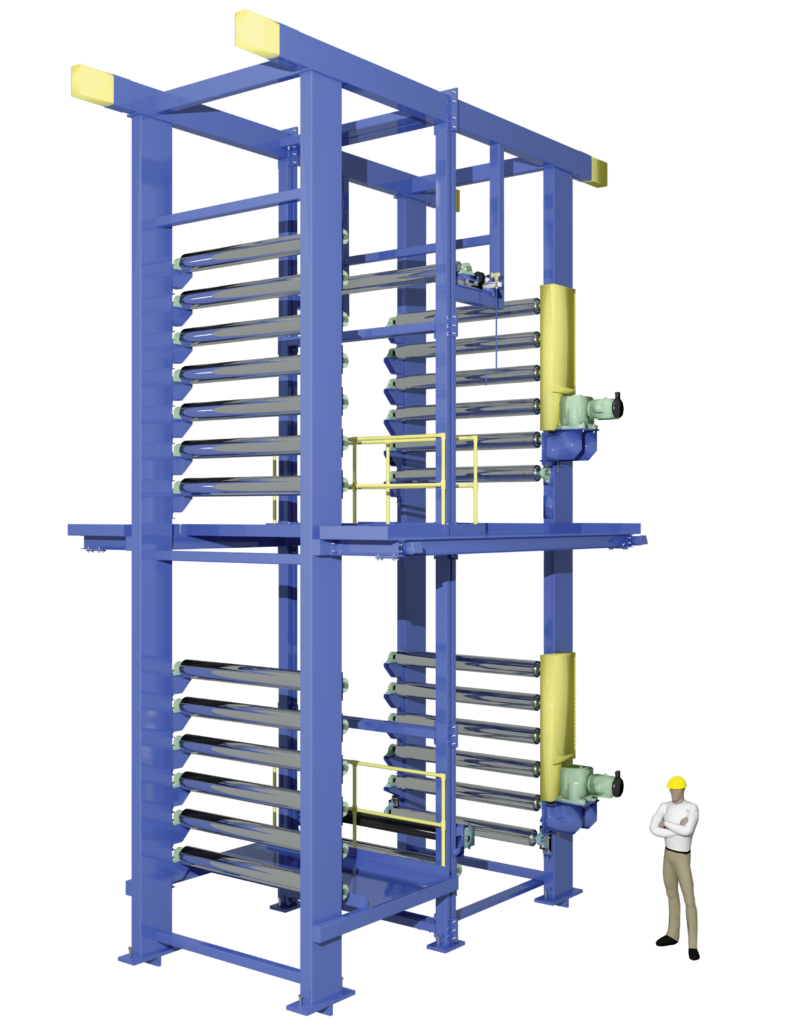

Tension Stands

Litzler tension stands isolate tension between the various process sections and are used throughout the entire line. We use proprietary software to determine the proper number of rolls based on: angle of wrap, coefficient of friction and speed. Roll sizes are calculated based on the tension and number of tows.

- Available in a wide range of widths (300mm – 4,000mm)

- Controlled via precision digital load cells

- Tension stands are driven through coordinated digital AC Vector Drives

- Drive control is through load cell feedback or “droop” control via recipe management

- Chrome plated or tungsten carbide finishes down to 1Ra

- Nip rolls are used during line stops

- Rolls are designed using Litzler’s standard deflection criteria to minimize deflection under load and keep the tow bands evenly spread