Litzler Custom Carbon Fiber Oxidation Ovens

Each Litzler Carbon Fiber Oxidation Oven includes the Patented End-Seal system. Litzler was the first company in the world to develop a practical End-Seal, with the first unit installed in 1995. The fifth generation End-Seal (G5) is now in operation.

- Uniform airflow, temperature and pressure

- Patented Litzler End-Seal chamber to eliminate the trapezoidal chamber in other designs

- 8” (200mm) thick insulation for safety and energy efficiency

- Proven and tested air supply and return nozzle configurations

- Electric and indirect gas heating

- Heat recovery for energy efficiency

- Modular and field construction designs available

- Seal-welded designs manage heat expansion

- Pilot and production systems are completely scalable

- Monitoring Systems

- Water Suppression System with stainless drain system

- Coordination with pollution control

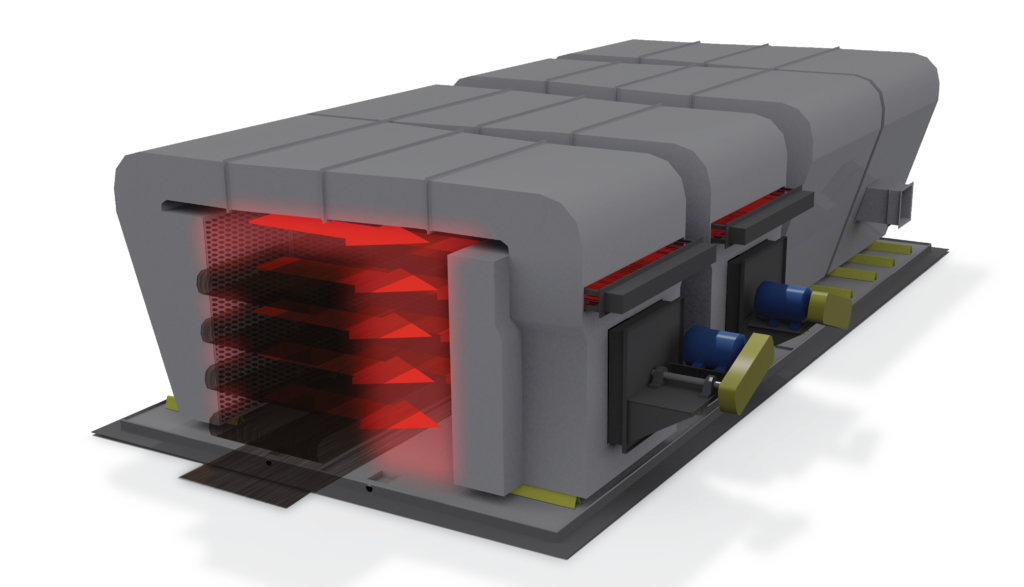

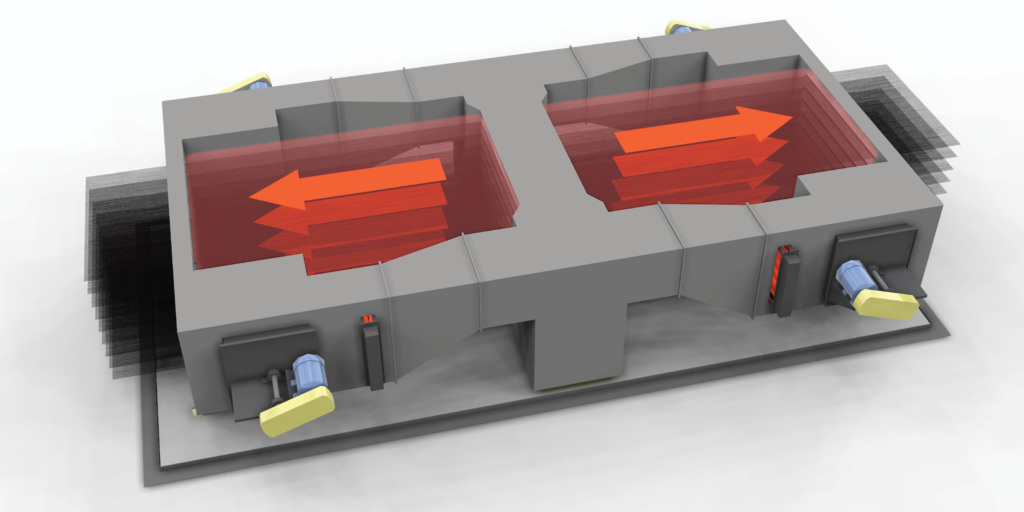

Cross-Flow Carbon Fiber Oxidation Ovens

Suitable for all fiber ranges (1-480k tow), Cross-Flow is the most forgiving technology for producing oxidized fiber. Cross-Flow Carbon Fiber Oxidation Ovens are proven in the field and continually improved via customer feedback and CFD engineering design.

- Cross-Flow encourages product uniformity by its very nature of alternating airflow directions across the fiber band

- High levels of uniformity allow the ovens to maximize speed and throughput

- Each tow experiences even, gentle airflow to promote controlled oxidation – Alternating airflow provides even treatment of each tow over the length of the oven

- Simple and clear airflow path through the heating system to maximize temperature, airflow and pressure uniformity

- Airflows up to 3mps are available depending on requirements

- Integrated heating/air systems mean smaller factory footprint

- Cross-Flow Oxidation Ovens have a 100% open interior for more efficient cleaning, threading and maintenance functions – No dead spots!

- Proven ovens with 300mm to 3,000mm wide tow bands

Parallel-Flow Carbon Fiber Oxidation Ovens

- Airflow is directed parallel to the fiber tow path

- Typically used for smaller tow with lighter oxidation oven requirements

- Air velocities up to 5 mps

- End-Seal design reduces tar formation versus existing designs

- Compact design compared to existing designs

- Improvements over competitive designs by integrating the Litzler Patent Pending G5 End-Seal chamber

- Parallel-Flow Carbon Fiber Oxidation Ovens are available in modular or field assembled configurations

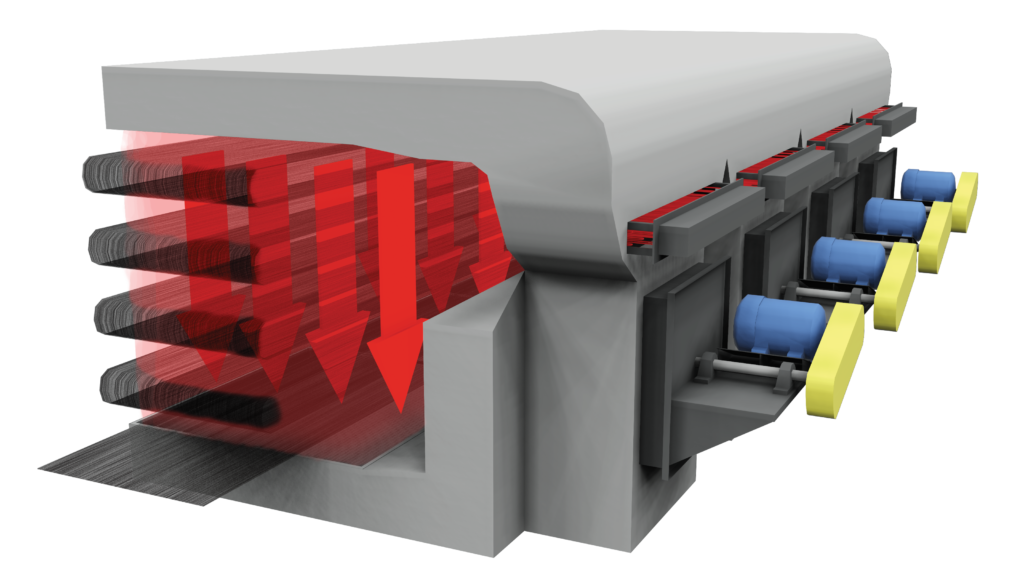

Down-Flow Carbon Fiber Oxidation Ovens

- Airflow is directed from the top down, through and around the tow

- Internal access for cleaning and thread-up

- Special plenum design for uniform airflow over the tow band

- Air velocities up to 5 mps

- Improvements over existing designs with field tested nozzles

- End-Seal design reduces tar formation versus existing designs

- Improvements over competitive designs by integrating the Litzler Patent Pending G5 End-Seal chamber

- Down-Flow Carbon Fiber Oxidation Ovens are available in modular or field assembled configurations

Heat Recovery

Carbon fiber production requires a tremendous amount of energy during the manufacturing process. Litzler engineers have developed methods of recovering heat from the pollution control system to save costs.

- Hot exhaust gases are treated in the pollution control device and fresh, clean, heated air is returned for use in the ovens as makeup air

- Hot air is returned under controlled pressure to maintain proper oven balance

- Recovered energy is used directly back in the ovens as heated makeup air

- Recovered energy can be maximized through air-to-air or air-to-oil heat exchangers